Contact Supplier

Mr. Liu Bin

Leave a messageBasic Info

Model No.: 75L Strengthen Type

Brand: Longxuan

Warranty: 1 Year

Control Type: CNC

Automatic Grade: Automatic

Power Source: Electric

Type: Open Mixing Mill

Additional Info

Packaging: Outside package of welding machinery:Sandard export wooden cases. Inner package of welding machinery: stretch film;or According to the customers\'orders.

Transportation: Ocean,Land

Place of Origin: China (Mainland)

Port: Tianjin,Qingdao,Shanghai

Payment Type: T/T,D/P

Incoterm: CFR,CIF

Product Description

Strengthen Type Rubber Kneader Mixer Machine

Introduction:

The mixing shaft is made of nickel & chrome alloy steel. The high abrasion part is additional welded with imported anti abrasion welding rod, then electroplating with hard chrome which is more

durable.

Advantage:

1. All main electrics are imported, the alternating current contactor is Shilin brand. The switch and button are Taiwan Tend or Siemens. The relay is Schneider, and the travel limit switch is Omron.

2. Hard tooth gear reducer with well-design structure, low noise, high efficiency and long service life.

3. The mixing chamber is bigger, the diameter of the air cylinder is bigger and gear reducer is also

bigger, which enhance the mixing effect,save mixing time and also save the cost.

4.The main mixing chamber is whole set casting by high anti abrasion alloy steel, after special dealing then electroplating with hard chrome.

5. The anti leakage unit of side wall is made of high-tech material which is wear-resisting and easy to maintain.

6. "M" shape of the pressure gland which make the mixing more thorough and even.

7. The main motor ampere meter is installed in the electrical control panel, under normal running,

when the pressure of the mixing chamber is too big, the current exceeds the set value, the connector will automatically adjust the gland`s up and down via the magnetic valve to remit

the pressure of the mixing chamber.

Main parameter:

| Mixing capacity(L) | 75L |

| Motor power | 132KW 6P AC |

| Material feeding | Front/back |

| Temperature adjustment | Steam heating or water cooling |

| Mixing capacity per batching | About 70-80kgs/time |

| Mixing time | 4-6 mins/batching |

| Rotor RPM | up to customer |

| Temperature difference | ±5º |

| gear reducer | ZLY-400 |

| Gear width | Input 115mm, output 145mm |

| Tilting angle | 140° |

| Main air cylinder size (mm) | 360×900 |

| Piston rod diameter (mm) | 120 |

| Mixing chamber size (mm) | 610×600×725 |

| Two rotors center to center space (mm) | 355 |

| Rotor bearing diameter (mm) | 150 |

| Machine size(mm) | 3900x2900x3400 |

| Machine weight(kg) | 10500 |

Overseas service

Outside package of Welding Machinery:Sandard export wooden cases.

Inner package of welding machinery: stretch film;

or According to the customers'orders.

About us

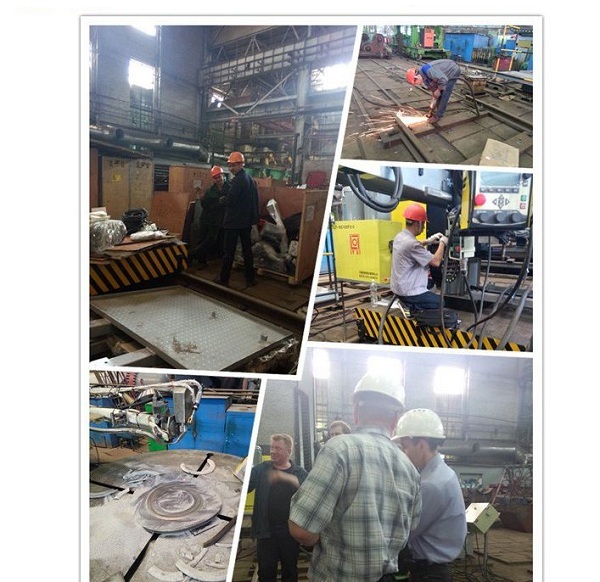

Shijiazhuang Longxuan Trading Co., Ltd. is located in Shijiazhuang, the capital of Hebei Province with convenient transportation. Our company was established in Feb. 2012. Our company is professional in supplying industrial equipment, covering pipe processing machinery, automatic welding equipment, Cutting Machine, etc. Our company always adheres to "credibility and integrity, efficiency" purpose and develops rapidly, creating excellent results and our company has fostered a good image in suppliers and foreign customers. And our company has established long friendly cooperative relationships with many high-tech machinery manufacturing enterprises.

Our company will continue to provide our clients with professional quality integrated solution in automatic welding, cutting and robot welding.

Product Categories : Plastic & Rubber Processing Machinery > Mixing Mill Manchine

Hot Products